Taking inspiration from nature: from photosynthesis to a low cost alternative to silicon technology in photovoltaic panels

Scientists from the Lausanne Swiss Federal Institute of Technology were the first to demonstrate a device capable of a sort of artificial photosynthesis for producing electricity

Nineteen years have passed since the original paper by Brian O'Regan and Michael Grätzel was published in Nature in 1991. These scientists from the Lausanne Swiss Federal Institute of Technology were the first to demonstrate a device capable of a sort of artificial photosynthesis for producing electricity. In their devices, as in the leaves of trees, a dye converts sunlight into another form of energy. These devices, known as dye-sensitized solar cells, or DSSCs, are actively investigated by universities, public research centres and private companies throughout the world.

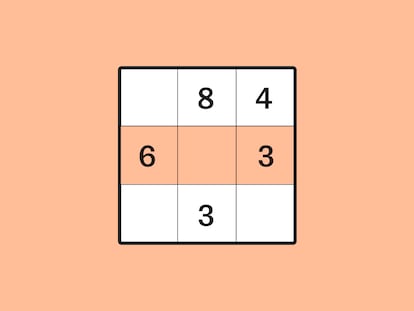

The public knows little, if nothing, about them. However, given the decision of US President Obama to boost research on renewable energies, it is probable that this solar technology will quickly become popular. One reason for its potential popularity is that, until now, it is the cheapest and it demonstrates the most favourable energetic balance. (Today's DSSC modules will have produced after 1-year of use the same amount of energy spent in their manufacture. This compares very favourably with the 4-year energy payback time of monocrystalline silicon modules, the most widely used photovoltaic devices of today). In contrast to silicon solar panels, they work even in low light conditions. Their structure is astonishingly simple and does not require sophisticated apparatus for their production. It is so simple that a kit to build small demonstration cells is available as an educational toy. Basically, a DSSC is made as follows. A piece of glass, electrically conductive on its surface, is coated with a titanium dioxide slurry.. This is a very cheap paint similar to those widely used for painting buildings. The titanium dioxide is then 'sensitized' (i.e. made sensitive to sunlight) with a light-harvesting dye. Once sensitized, the titanium dioxide-coated glass panel is glued to another piece of conductive glass covered with a catalyst (platinum is the best choice, but also lampblack is good for the purpose). The space between them is filled with an iodine-based solution, similar to that used for disinfecting. That is all. Nothing more, nothing less. However, there are still some serious problems to be solved. The first of these is the dye. The best performing dyes require the use of a very rare (and expensive) metal, ruthenium. Though this does not present a cost problem, because the amount of dye needed per unit surface is negligible, it can be problematic if one imagines the mass use of this technology (ruthenium is the rarest naturally occurring chemical element).

Furthermore, these dyes are not capable of absorbing (and so converting to electrical energy) the full solar spectrum, i.e. all the 'colours' that make up sunlight. Second, the filling solution requires a very reliable sealing of the cell to avoid leaks and, consequently, cell failures. Third is the thermal and long-term stability of the cell, because the dye and some substances present in the filling solution tend to degrade over time, and the higher the temperature the faster the degradation.

Fourth, the efficiency is about half that of the silicon devices. All these problems are under intense study by scientists, as shown by the ever increasing number of scientific articles on this topic published annually (422 in 2005, 504 in 2006, 563 in 2007, and 681 articles in 2008). Considering that this is a quite young technology, one can expect significant advances. New promising, ruthenium-free, bio-inspired dyes based on porphyrins (compounds chemically related to chlorophyll, the molecule that allows photosynthesis in plants) are being developed. A great deal of research is being done in order to replace the iodine-based solution with solids having similar properties to overcome the sealing problems and some of the stability ones. Nanomaterials, such as carbon nanotubes, are expected to improve the performance of titanium dioxide coatings, when properly dispersed in them. These facilitate electrical current transit. (I am working on this particular topic together with other people from my Department). Simple plastic anti-reflection films, such those used for laptop screens, eyeglasses, etc. can also improve DSSC performances by minimising the light losses. Particular formulations of titanium dioxide paints with optimised particle sizes and shapes also improve light harvesting efficiency. So, many battlefronts are opened for the improvement of this promising technology. Very active research groups exist in public institutions in China, Japan, Switzerland, U.S.A. and South Korea, while private companies - Sharp, Sony, Fuji, TDK, Samsung - are also developing DSSC technology.

Alessandro Latini, University of Rome La Sapienza www.atomiumculture.eu

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.